How to solder - an introductory guide:

If you're new to soldering our Soldering School will have you up and running in no time.What is soldering?

Soldering is a process for joining metals. In soldering the metals to be joined are 'glued' together by melting another metal, whose melting point is lower than the metals to be joined. Other similar metal joining processes include welding and brazing. Brazing is a stronger, higher temperature version of soldering. The Welding Institute defines the difference between soldering and brazing as the temperature at which the filler metal melts. Below 450 °C the process is soldering, above 450 °C it is brazing. Solder is available in several different alloys. Before the Restriction on Hazardous Substances (RoHS) legislation electronic solder was typically made from an alloy containing 60% Tin and 40% Lead. This melts at 183 °C RoHS legislation restricts the use of lead, and other metals, in electronic assemblies. This has led to the development, and widespread use, of lead free solders. Typical lead free solders contain mostly tin, with small amounts of copper, and silver. The melting point varies with the alloy, but is typically 220 °C to 240°C.

Solder is available in several different alloys. Before the Restriction on Hazardous Substances (RoHS) legislation electronic solder was typically made from an alloy containing 60% Tin and 40% Lead. This melts at 183 °C RoHS legislation restricts the use of lead, and other metals, in electronic assemblies. This has led to the development, and widespread use, of lead free solders. Typical lead free solders contain mostly tin, with small amounts of copper, and silver. The melting point varies with the alloy, but is typically 220 °C to 240°C.

Why Flux?

Heating metal in the air causes oxidisation. This is a cause of poor joints. To prevent this solders need to have a flux. Solders for hand assembly of electronics usually include the flux as part of the solder. The manufacturer has selected the most appropriate and incorporated it in tiny holes that run in the wire.The Lessons:

Click on the lesson name in the table below to go to the lesson.| Lesson No#. | Lesson Name. | Description. |

|---|---|---|

| Introduction. | If you're new to soldering our Soldering School will have you up and running in no time. | |

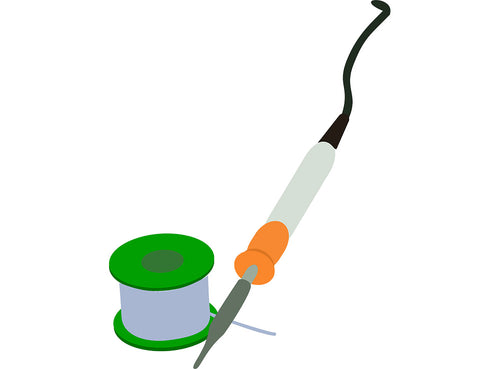

| 1 | Soldering Equipment Explained. | A quick guide to the basic tools you'll need before you start. Includes a video explanation of some tools. |

| 2 | How to Clean your Soldering Iron (Tinning). | An explanation of why we need to clean the tips and a step by step guide. Includes a video guide to tinning. |

| 3 | How to Solder in Ten Easy Steps. | A practical guide to getting started soldering. Includes a troubleshooting guide and examples of good and bad solder joints. |

| 4 | De-Soldering Demystified. | A guide to removing solder. Includes a video demonstration. |

| 5 | Simple circuit board repair. | Sometimes a pad might get damaged on your board. We show you how to fix it in this simple to follow guide. |

©Kitronik Ltd – You may print this page & link to it, but must not copy the page or part thereof without Kitronik's prior written consent.

3 comments

Harrison

hi which method of soldering do most schools use eg through-hole or surface mount

Mark Donnison

Hi George, Thanks for the comments, it's always great to get insights from professional educators.

George Spiridis

Have been teaching students the soldering process to the range of ages 10yrs old to 18yrs old since 1992 in Australia (prior to Education trained and worked in the Electrical/Electronic Industry for 23yrs. May I suggest. When I have demonstrated the process of soldering I use language such as “It is a Metallurgical Bond” between three metals: The components, The Copper Tracks/Wires, The Solder. When the term “Gluing” is used the students try and use all sorts of methods from their prior knowledge bank and experiences of using different glues and materials to stick together stuff.(some weird stuff happens) When I use the term Metallurgical Bond, they understand that they have to heat The components, The Copper Tracks/Wires together at the same time and then add the solder to the tip of soldering iron while components are hot. This turns the solder into a molten state so it flows into the junction of the The components, The Copper Tracks/Wires. (In a very short period of time) They see/experience and understand a “Metallurgical Bond”. Their soldering joints rarely fail. The students are more successful when the above explanation is given while a soldering joint is demonstrated in front of them. There is a lot more I can suggest but for now I hope that this information is helpful. © George Spiridis 2019 Kind Regards George Spiridis