There are a vast range of different types of plywood (laserply) available, all of which have been produced to meet different types of requirements. Understanding the many different characteristics can be confusing. We have put together this simple guide to help you understand the many options in a simple way.

Plywood (laserply) Surface Grading / Qualities

Wood, due to its very nature varies in appearance from one piece to the next. A plywood grading system is used to specify aspects of the finished look of the plywood, thus allowing the user to select a material that is suitable for their application. Grading rules vary depending on the country in which the plywood is produced and the following information is a typical guide only and may not be accurate for all plywood. Please refer to the product specific information that can be found on the relevant product descriptions.

Gradings that feature an /, eg AB/BB, informs you that in this case the front face is AB and the rear face is BB. For end results that need to be aesthetically pleasing on one side only, you can afford to have a good side and a lesser side. If you need a high quality finish on both sides, then a grading of AB/AB would be desirable.

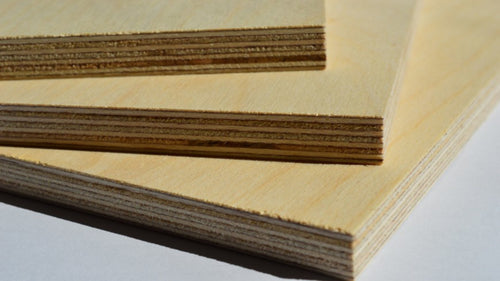

AB grade

This is a very high quality grading (typically the best you will see). The surface of the material will be consistent in appearance with no large variations in colour. Small pin knots are allowed and these would typically be only a few mm in diameter.Above is a photograph of our AB grade Italian Poplar plywood

BR ‘veneer’ grade

This is similar to B grade material, though knots would typically not exceed 7mm to 8mm in diameter. It shows the natural look of the wood and will show natural colour variations. This grade is used for some of our thinner plywood’s. These thinner materials are used in specialist applications and tend to have a slightly higher quality feel. The surface of the material is typically of a smoother finish than that of most plywood’s.Above is a photograph of our BR ‘veneer’ grade Birch plywood

B grade

This grade shows the natural look of the wood. There will be changes in colour that show the grain pattern. Sound, smooth knots are allowed and these will typically be under 15mm to 35mm in diameter (depending on the countries grading rules). The surface should normally be free from open knots and plugs. The material should be suitable for paint / stain or a lacquered finish.

Above is a photograph of our B grade Birch plywood

BB grade

This grade is similar to B grade but allows for larger knots and repairs to the face. Sound, smooth knots are allowed and these will typically be under 50mm in diameter. Open knots can be repaired with wooden plugs. The material should be suitable for applications where the visual look is not critical.

Above is a photograph of our BB grade Birch plywood.

This piece has a plug but knots are also allowed.

C grade

This grade of plywood is ‘structurally’ sound but allows for defects on the surface of the material. These defects can include open knots, discolouration, and splits. These defects mean the material is suitable for applications where the strength of plywood is needed but the appearance does not matter. Kitronik does not supply any C grade plywood.

CC grade

This is often used as the underside of veneers, as used on our 3.6mm Oak Veneer Plywood. The structure is sound but there will be defects on the underside of the material. These can include open knots, discolouration, and splits. These defects mean that our veneered plywood is suitable for applications where only one good face is needed.

Above is a photograph of C grade Birch plywood

Note: It is worth remembering that these are ‘worst’ case conditions and the majority of a sheet may actually meet one of the higher classifications.

| Useful Laser Plywood (laserply) Resources. |

|---|

| What Is Laser Plywood (laserply). |

| Plywood: The Production Process. |

| Plywood glue types and classifications. |

| Looking after your plywood. |

| How is Poplar Plywood Different to Birch Plywood? |

| A Guide to Plywood Grading. |

| A guide on using laser materials. |

©Kitronik Ltd – You may print this page & link to it, but must not copy the page or part thereof without Kitronik's prior written consent.

8 comments

Mark Donnison

Hi Rick, that would depend on the application, ie what loads they would be required to deal with. You might find that thicker MDF might be a better fit for some tasks, you could always add a plywood layer for a better-looking finish.

rick nugent

Hi, I need to fit out my coffee van with structures to divide the van and build the counter, cupboards etc, what grade and thickness of plywood would you recommend/ thanks

Mark Donnison

Hi Gary, we tend to find that for most applications the finish on AB is good as is. For some applications, you may prefer to do a little light sanding.

Gary

I've been using BR grade for laser cut for a while and give a good finish that is good enough to leave as is. (i.e. No sanding or varnish). I understand that AB grade is better quality overall but does it have the same fine finish as BR and that it could be used in the same way?

Rob Haywood

Hi Graham, You would need to find a supplier who deals with building grade plywood. Our plywood is specifically for laser cutting etc. Rob

graham burton

hi, what type and thickness of plywood should I use on top of a wet (plastic pipe) underfloor heating system set around cement slabs. Thanks

Rob Haywood

Hi David, We're by no means experts on exterior grade (as all of our is for interior) but our guide here https://www.kitronik.co.uk/blog/plywood-glue-types-classifications/ might be of use. In particular you're after EN636-3 classification. Rob

David moss

Have been very disappointed with recent plywood purchases in that delamination has occurred within a short period of time( WBP grade) . Not from your company I hasten to add . How can I ensure that the glues are up to an exterior application .Look forward to hearing from you.many thanks in advance.